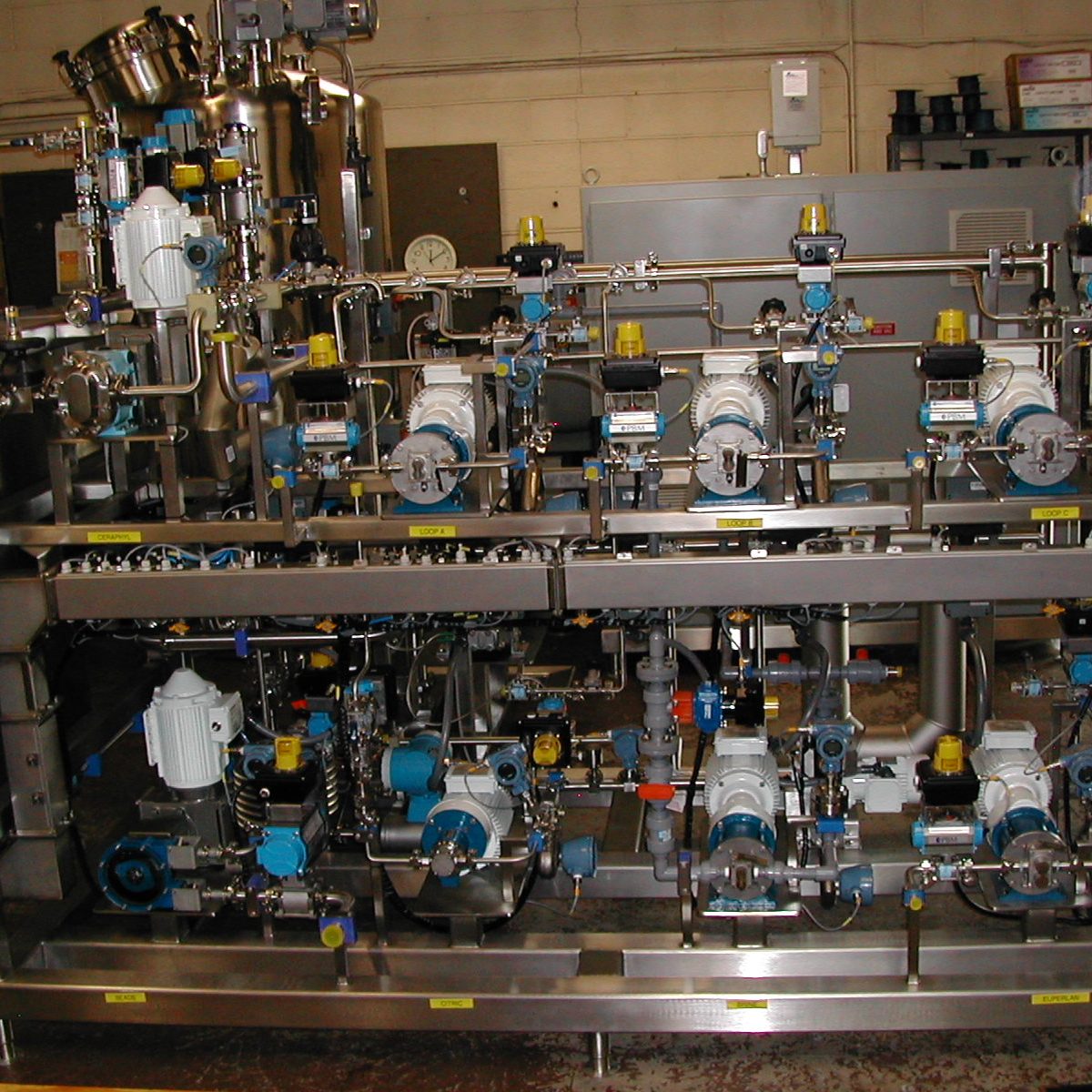

Modular process skids for food and beverage are often an overlooked option for improving production. From daily operations and hygienic cleaning to passing regulatory inspections, modular process skids are an ideal solution for modernizing production. Modular process skid designs can meet the strict, often unique, manufacturing standards and requirements for food and beverage production.

Implementing modular process skid systems is an increasingly common tactic among manufacturers in the biotech, cosmetics, and food and beverage industries across the USA. This article introduces compelling reasons to utilize modular skids to replace, increase or diversify production.

Hygienic pumping and mixing systems are pivotal in various industries, including food, pharmaceuticals, and biotechnology. These systems ensure that liquids, powders, and other materials are transferred and mixed without contamination. These systems are designed to minimize bacterial growth and withstand rigorous cleaning processes while maintaining operational efficiency. The best designs incorporate ...

Clean-in-Place (CIP) process skids represent a critical advancement in industrial hygiene, enabling automated cleaning of processing […]

Hygienic process skids for HBA products are a popular type of specialty manufacturing process equipment. In the HBA products manufacturing environment, maintaining stringent hygiene standards is mandatory. As consumer awareness of product safety (brand integrity) increases, manufacturers must ensure that their production processes mitigate public safety problems resulting in brand degradation. These goals are best achieved by excellence in process skid design and engineering.

In the food, beverage, pharmaceutical, and personal care industries, maintaining the highest levels of sanitation is paramount. One essential solution that has emerged is the sanitary processing skid. These systems are meticulously designed and engineered to ensure safety, hygiene, and efficiency in manufacturing processes. In this blog post, we will explore the various types of sanitary processing skids, their uses, benefits, and best practices for implementation.