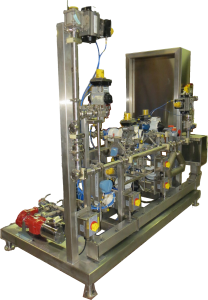

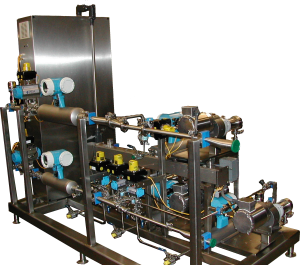

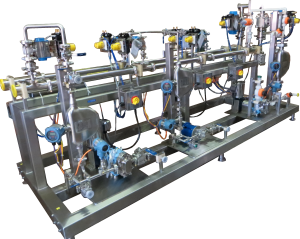

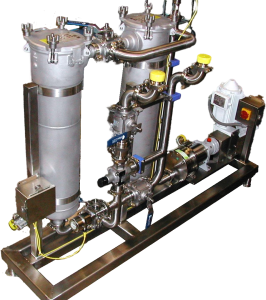

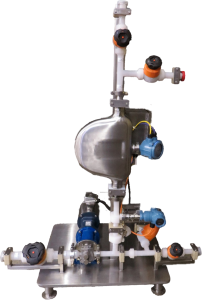

Sanitary Process Skids, are custom-designed to be a compact system widely used in industrial fluid processing. It consists of integrated components and equipment designed to perform specific functions such as heating, cooling, mixing, blending, dosing, and solution preparation. What sets our process skid designs apart is their adherence to strict sanitary standards, making them ideal for industries where hygiene and product purity are critical, such as pharmaceuticals, food, beverage, and biotechnology.

MODULAR DESIGN

Our modular design approach enables critical customization with components, instrumentation, and controls to suit specific production needs. Another advantage of the modular design is the process skid is built offsite, tested, and delivered with only the need of plant utilities and raw materials to be connected. This allows for rapid installation and process portability if the site moves. Enjoy a streamlined and efficient solution for tough processing challenges. Our process skids facilitate production efficiency while maintaining quality which ensures the integrity of the final product.

Typical Sanitary Process Skids:

- Heat Exchange–Process Heating/Cooling

- Pumping and Metering

- Continuous Process Production

- Late product addition: (Fragrances, Color, Other)

- Tank mixing / blending

- Process Mixing & Blending (Static or Dynamic)

- Batch Process / Dosing

- Solution Prep

- Fermentation / Bioreactor

- Utility Skid