Modular Process Skids for Food and Beverage Processing

Modular process skids for food and beverage are often an overlooked option for improving production. From daily operations and hygienic cleaning to passing regulatory inspections, modular process skids are an ideal solution for modernizing production. Modular process skid designs can meet the strict, often unique, manufacturing standards and requirements for food and beverage production.

Solving Common Opertional Challenges

Efficient, scalable, and hygienically designed, modular process skids have transformed food and beverage manufacturing by enabling rapid deployment and operational flexibility. Companies striving to meet evolving USA hygienic processing standards and regulations should explore the advantages of custom-designed modular skids. Ideally, these companies will choose to work with a manufacturer in the USA.

For example, Arcadia Equipment in Kennesaw, Georgia, is a food and beverage process skid manufacturer in the USA. Arcadia Equipment has decades of design and manufacturing experience in the food and beverage industry. Arcadia Equipment is known as an expert on production and regulatory standards for food and beverage processing companies.

Understanding Modular Process Skids

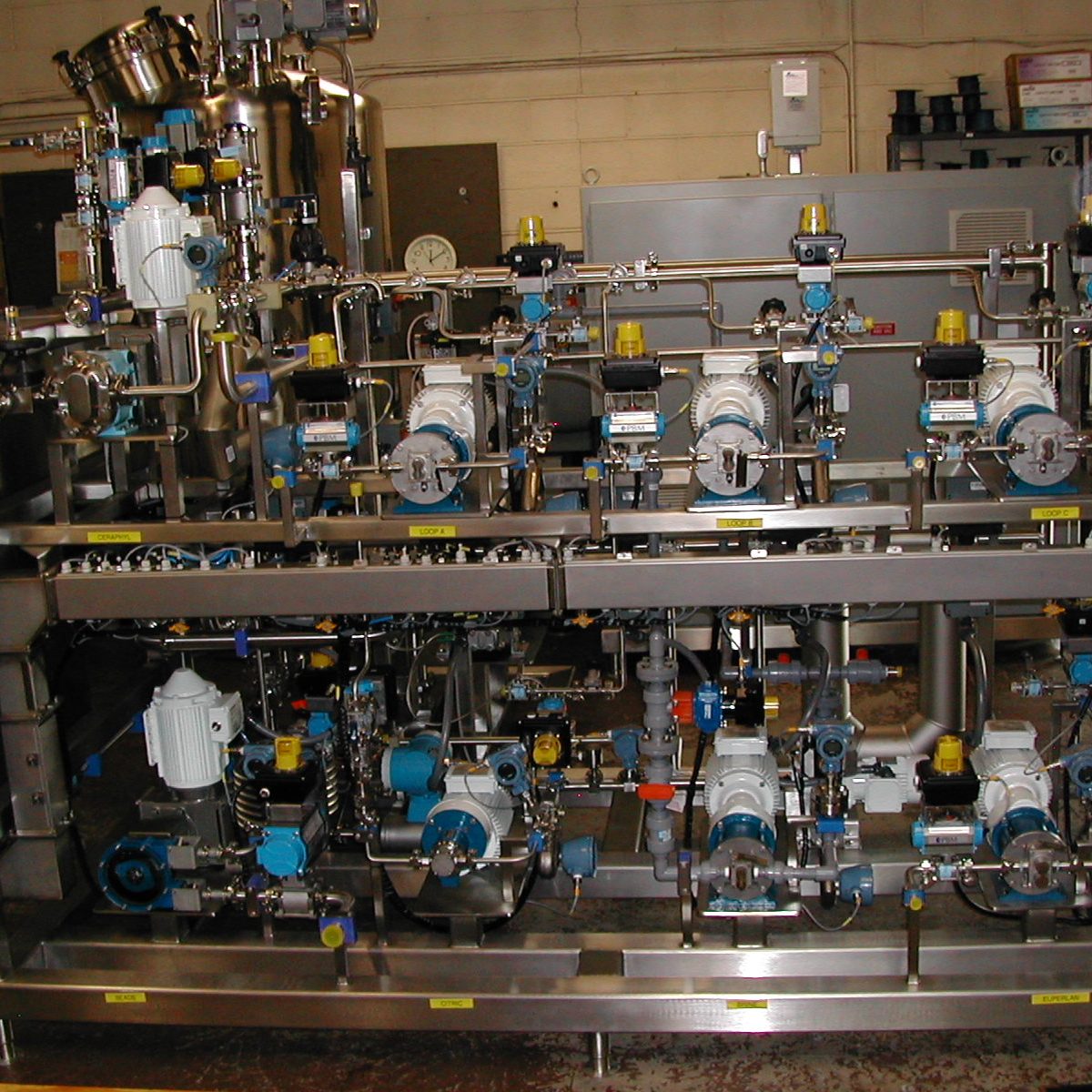

Modular process skids are fully assembled, pre-engineered process units constructed on a rigid frame that integrates all necessary components, including pumps, valves, sensors, piping, controls, and instrumentation. These self-contained units allow entire process segments to be built offsite, then transported and installed with minimal disruption.

This modular design approach offers key advantages for food and beverage processing facilities:

- Minimized installation time and reduced on-site construction

- Streamlined quality control through factory assembly

- Enhanced flexibility for process changes or expansion

- Improved sanitary design meeting stringent hygiene standards

- Compact footprint optimizing plant layout

Why Modular Skids Matter in Food and Beverage Manufacturing

The food and beverage industry faces unique production challenges. Strict regulatory environments require equipment that minimizes contamination risks, facilitates easy cleaning, and ensures consistent product quality. Modular skids simplify these requirements through precise engineering and material selection tailored for sanitary applications.

Manufacturers value modular skids because this approach:

- Facilitates compliance with FDA, USDA, and 3-A Sanitary Standards

- Reduces downtime during production shifts or line changes

- Allows faster ramp-up for new product lines or scaling existing ones

- Supports automation integration within the skid’s control systems

Arcadia Equipment: Leader in Modular Process Skids in the USA

Based in Kennesaw, Georgia, Arcadia Equipment stands out as a premier manufacturer specializing in modular process skid solutions for food and beverage processors. Their approach combines deep industry knowledge with innovative fabrication techniques, emphasizing USDA and food-grade sanitary compliance across all projects.Key Strengths of Arcadia Equipment

- Custom skid design tailored to the client’s process specifications

- Stainless steel fabrication with hygienic welding and finishing

- Integration of advanced instrumentation and automation controls

- Comprehensive testing, including factory acceptance and sanitary clean verification

- End-to-end project management from concept through installation

With a focus on quality and customer satisfaction, Arcadia ensures each skid delivers repeatable performance while conforming to the highest sanitary and safety benchmarks.

Key Components in Food and Beverage Process Skids

The modular skid’s performance and reliability depend on precise component selection and system integration. Typical components include:

- Pumps: Positive displacement or centrifugal pumps designed for gentle handling or high-capacity transfer

- Valves: Sanitary diaphragm, butterfly, or ball valves fabricated from FDA-approved materials

- Heat exchangers: Plate or tubular heat exchangers for pasteurization and temperature control

- Sensors: Flow meters, pressure transducers, temperature sensors supporting automation

- Piping and fittings: Clean-in-place (CIP) capable stainless steel tubing with hygienic clamps

- Control panels: Programmable logic controllers (PLCs) with HMI interfaces for process monitoring and data collection

The integration of these components is customized around process requirements such as mixing, filtration, carbonation, or sterilization.

Engineering and Fabrication Excellence in the USA

Manufacturing modular process skids domestically offers distinct advantages over offshoring or generic equipment purchases. U.S.-based fabricators like Arcadia Equipment in Kennesaw, Georgia, leverage state-of-the-art facilities, skilled tradespeople, and strict quality assurance protocols to deliver superior reliability and compliance.

Benefits of Domestic Manufacturing

- Closer collaboration with clients for on-demand design iterations and testing

- Access to local raw materials certified for food-grade use

- Accelerated project timelines due to reduced shipping and customs delays

- Supporting local economies and maintaining supply chain resilience

- Incorporation of the latest technology and adherence to American manufacturing standards

Customization and Scalability for Diverse Food and Beverage Processes

Every food and beverage manufacturer has unique and variable production process needs. A processing plant may sometimes need to reconfigure its process flow, including relocating equipment. Modular skids are the solution for meeting present and future production processing needs.

Examples of Tailored Skid Types

- Liquid handling skids for juices, dairy, and alcoholic beverages are optimized for low shear handling

- Powder dosing and blending skids with integrated weighing and feeding controls

- Carbonation and CO₂ injection skids for soft drinks and sparkling water production

Additionally, sanitary CIP skids are designed to automate and streamline cleaning between batches. Scalability is achieved through modular expansion options, allowing manufacturers to increase capacity or add features with minimal downtime.

Quality and Compliance

Food and beverage processors operate under rigorous oversight from governmental and third-party agencies to ensure consumer safety. Modular process skids must meet or exceed standards, including:

- FDA Current Good Manufacturing Practice (CGMP) regulations

- USDA sanitary design guidelines

- 3-A Sanitary Standards for milk and dairy equipment

- NSF International certifications for food equipment

Arcadia Equipment incorporates these criteria into every project phase—from design through fabrication and testing—to assure regulatory compliance and risk mitigation.

Integration with Automation and Digital Controls

Modern process skids are not merely mechanical assemblies; they include sophisticated digital controls that enable real-time monitoring, process optimization, and predictive maintenance. Integrated PLCs and HMIs allow operators to adjust parameters, log critical data, and interface with plant-wide systems.

Arcadia Equipment integrates automation solutions that align with Industry 4.0 initiatives, enabling clients to:

- Track production metrics remotely

- Automate sanitation cycles, thus minimizing contamination risks

- Apply data analytics for continuous process improvement

Sustainability Considerations in Modular Skid Design

Sustainability is an emerging priority influencing equipment design and operation. Modular process skids can reduce energy and water consumption by optimizing flow rates, minimizing process waste, and facilitating efficient clean-in-place (CIP) cycles.

Arcadia Equipment emphasizes eco-friendly materials and energy-efficient components while maintaining necessary hygiene standards. These sustainable practices help manufacturers align with corporate responsibility goals and regulatory incentives.

Common Mistakes to Avoid When Selecting Modular Skid Manufacturers

Partnering with the right manufacturer is crucial. When evaluating options, manufacturers should be wary of the following pitfalls:

- Choosing purely on price without verifying sanitary certifications and design expertise

- Overlooking local codes and regulations that impact equipment installation

- Failing to account for future scalability and process changes

- Neglecting integration capabilities with existing automation infrastructure

Selecting a seasoned, US-based supplier like Arcadia Equipment mitigates these risks through transparent project management and tailored engineering services.

Future Directions and Innovations in Process Skid Manufacturing

As food and beverage processing advances, modular skid systems are evolving with emerging technologies:

- Enhanced material options, including advanced polymers and antimicrobial coatings

- Increased use of digital twins for virtual testing and process optimization before fabrication

- Modular designs enabling ultra-fast reconfiguration for new product launches

- Integration of AI-based predictive maintenance for minimizing unplanned downtime

Arcadia Equipment’s commitment to innovation positions it to deliver next-generation modular skids that anticipate and exceed market demands.

Modular process skid manufacturing in the United States, particularly through expert providers like Arcadia Equipment in Kennesaw, Georgia, offers unmatched value for food and beverage processors. These units are engineered to optimize sanitary standards, accelerate production timelines, and provide scalable process solutions.

By leveraging domestic manufacturing expertise and embracing technological innovation, the industry gains resilient, high-performance equipment that supports long-term growth and compliance. Choosing a partner with demonstrated specialization in modular skid solutions ensures your operation can adapt swiftly while maintaining the rigorous quality and safety standards consumers and regulators demand.

Planning to Improve Production?

If your business needs to improve or augment production, we encourage you to reach out to Arcadia Equipment. Let’s discuss your needs and situation to find practical, cost-effective solutions. Feel free to call us at 770-509-1470 or contact us online.

No responses yet